Modular Rack Structures for HI-FI Audio Equipment

Modul Rack: Lightweight and precise

Universal Rack: Robust and versatile

Power Rack : Indestructible for heavy-duty applications

Modul Rack

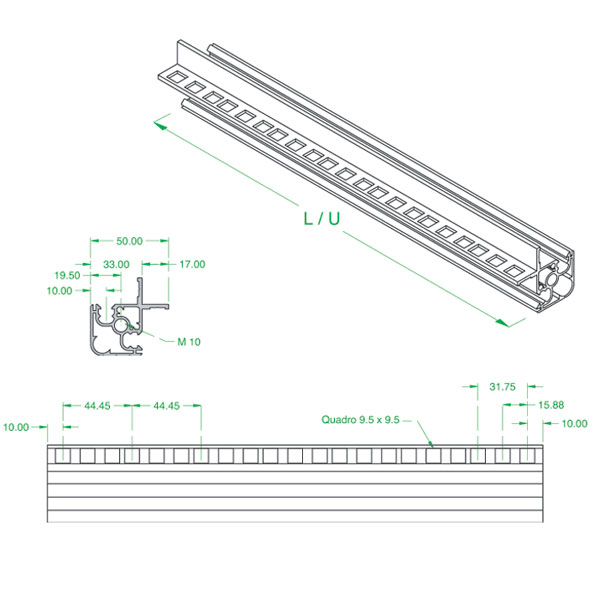

The aluminum structure called Modul Rack allows the creation of 4-profile structures of medium-small size with a width of 19" or less.

This modular aluminum structure is made up of 8 three-way joints onto which 12 aluminum profiles with rack-pitch perforated fins are bolted.

With the ModulRack structure it is possible to create 84HP (TE) wide frames * equivalent to 19'' and smaller width structures: 60 HP = 328 mm, 42 HP = 237 mm,

* TE or HP (Horizontal pitch) is a unit of measurement typical of the world of printed circuit boards and defines the width of the devices mounted in subracks, 1TE or HP corresponds to 0.2 inches (5.08 mm)

- ModulRack frames have codes in the form TV(A,B,C)xxxx where the 3rd letter after the prefix TV (A,B,C) identifies the width of the container:

A=84HP (19'') 451 mm internal (TE), 525 mm external dimensions

B=60HP 328 mm internal (TE), 402 mm external dimensions

C=42HP 237 mm internal (TE), 311 mm external dimensions

the final part of the code, composed of 4 digits, identifies the number of units (U first 2 digits) and the depth (last 2 digits).

Universal Rack

Universal Rack is a modular structure with which to create large, solid 4-profile frames , 19" wide or more (up to 4 metres per side).

The frames in this series have codes in the form TRhhwwdd where after the letters TR we find 3 pairs of numbers that determine the dimensions of the structure expressed in rack units: height the first 2 digits, width the central 2, depth the final 2.

In 10U = 551 mm wide frames (TRhh10dd) the 19” objects are installed directly on the front and rear uprights (L=551 mm external corresponds to 19" internal).

In 11U = 596 mm wide frames (TRhh11dd) the 19" system is created with special 19" reduction rack uprights in steel, codes ARMA.ML 19xx (where xx indicates the number of units) n.7 in the exploded view, or in aluminium n. 6 in the exploded view.

In frames wider than 11U (for example in 16U = 818 mm - TRhh16dd) the ARMA.ML 19xx reduction uprights are fixed on special crosspieces located on the base and top of the frame.

Frame composition:

1 - Extruded aluminum profile code pr XX u (where XX indicates the length expressed in number of rack units) To make a complete frame, 4 extruded profiles are needed for each size, i.e. 12 pieces in total.

2 - Corner joint code ARMA.TRC-2002 - 8 pieces are needed for 1 frame

3 - Corner cover code ARMA.TRC-C2002 (or code ARMA.TRCFC2002 perforated cover) - 8 pieces are required for 1 frame

4 - Socket head cap screw code ARMA.B-10-30 - 24 pieces are needed for 1 frame

5 - Internal 19” aluminum upright code ARMA.ML-2-XX where XX indicates the number of rack units *

6 - External 19” aluminum upright code ARMA.SP XX where XX indicates the number of rack units *

7 - 19” internal steel upright code ARMA.ML 19/XX where XX indicates the number of rack units *

*The 19" reduction uprights, ARMA.ML-2, ARMA.SP and ARMA.ML 19, are required in frames with a width of 11U equal to 596 mm (TRxx11xx) and are fixed to the holes in the profiles that create the depth or in frames with a width of 16U equal to 818 mm (TRxx16xx) and are fixed to the ARMA.SML.XX support crosspieces mounted at the bottom of the frame and at the top of the roof.

Universal Rack Models

Power Rack

Power Rack is a modular steel structure ideal for creating sturdy frames and cabinets with 4 or more profiles and 19" or larger width

Power Rack frames are "cage" structures made with aluzinc-treated steel profiles inserted into three-way joints, ideal for heavy-duty applications, guaranteeing robustness and functionality even with heavy loads, specifically designed for applications involving battery packs, ferrite cores, toroidal transformers, and electromechanical components.

2 mm thick tubular steel frame assembled using 3-way joints secured by screws, completely disassembled for easier transport, available in natural Aluzinc, painted RAL 7035 or any colour on request.

Like all "cage" frames, they can be completed with a roof, bottom, sides, and doors, transforming them into sturdy cabinets closed on all sides or only partially depending on specific needs.

The coverings such as the roof, sides and doors close flush, ensuring an excellent seal and a very high level of aesthetic result. They can be solid, ventilated, with fins of various types and sizes, light wells, tempered glass windows, plexiglass or other according to customer specifications.

The ability to mount wheels either directly on the corners of the structure or on special crosspieces allows for the creation of single structures with more than 4 wheels and therefore capable of distributing significant weights more evenly.

Power Rack Models